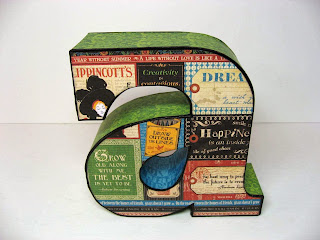

Ever since Graphic 45 came out with their Typography paper line I knew I wanted to try to make 3-D alphabet letters. So here is what I came up with... the letter "a" and the letter "z".

Ever since Graphic 45 came out with their Typography paper line I knew I wanted to try to make 3-D alphabet letters. So here is what I came up with... the letter "a" and the letter "z".Each letter is 6 inches by 6 inches, and 2 inches thick.

They are completely made out of chipboard and are hollow inside.

Here are some close-ups....

The "a"

and the "z"

The camera angle is a little odd on this one - it really is pretty square.

I covered the back with a different pattern;

here's what it looks like on the "a"...

I did take some photos as I went along so I could explain the process...

I started out by printing extra large font size letters on my computer and then enlarging them to 6" x 6" - that's the blue square outlineyou see in the picture. For the "a" I needed to spread it out width-wise, so I cut it on the red line to get the correct size. I pulled the top part to the left and the bottom to the right.

After I had the pattern I cut it out twice in black chipboard for each letter. I did a little sanding and tried to get them as close to being identical as possible without making myself crazy.

I then traced each side onto a piece of plain kraft colored chipboard. I drew a line about 1/16 of an inch inside of the traced image - this was the cutting line. (I also traced the smaller image to use later as a template for cutting the decorative paper.)

The plan was to glue the smaller kraft chipboard letter onto the larger black chipboard. This would give a small ledge to be able to glue the chipboard which would give the letters their depth.

Look carefully in this picture and you can see the kraft chipboard on top of the black chipboard for the "z". (I'm working from the back here, so the letter is reversed.)

So each letter has 4 pieces of chipboard - the back has an outside layer (black) and inside smaller layer (kraft) and the front has an outside layer (black) and a smaller inside layer (kraft). Sharp craft knife blades are a must have!

It actually went together much more easily than I expected. On the straight-aways, I just measured the length of the kraft on either side of a corner and joined them with a cardstock joint on the inside.

On the curved sections, I used my paper trimmer to lightly score the chipboard every 1/8" inch. You can see the score lines in this picture.

I joined smaller sections together to make four pieces and then glued each one of those on until the entire letter was complete.

Putting on the other side (front) was a little like herding cats. I finally figured out that I couldn't glue the whole thing at once (duh) and then just worked around until it all fit into place. I did use a couple of rubber bands in strategic places to help hold everything in the proper place.

Being able to control the amount of glue is critical. I have a marvelous precision tip glue bottle that a friend gave me. I think it's primary purpose is for quilling projects, but not a project goes by that we don't use it on - it was certainly handy for this one.

The only conundrum for the "a" was how to cut a neat inside circle. Then I remembered I had a magnetic Tim Holtz circle die that was just about the right size. Since the letters were 6", they just fit in the die cutting machine - whew. Here's a picture showing how I used blue painter's tape to get the die positioned properly.

I assembled the "a" in much the same way as the "z"- just took my time and glued each section as I went along. Here you can see a section being held in place with clothespins until it dried.

Once both letters where completed I used the template I created from the smaller chipboard to cut the decorative paper. I used this size because I wanted to have a small outline of black around the decorative paper to make it pop.

I cut 2" strips of other paper to go on the sides - it fit nicely and covered all the joints for a seamless finish.

This was a fun project to engineer. I now know more about working curves in chipboard which will come in handy in making other designs.

And here's a little funny... my niece said to me after seeing these two letters...."are you going to make the rest of the alphabet?" Answer... "Nooooooooooooooooooooooooooooo!"

No comments:

Post a Comment